Reverse Engineering

Why Chose Norway Labs

U.S. Based

All reverse engineering services are performed at our facility in Beaverton, OR

No Limits

Our system does not have a layer limit or a size limit.

Accuracy

Our processes result in the accurate reconstruction of legacy boards

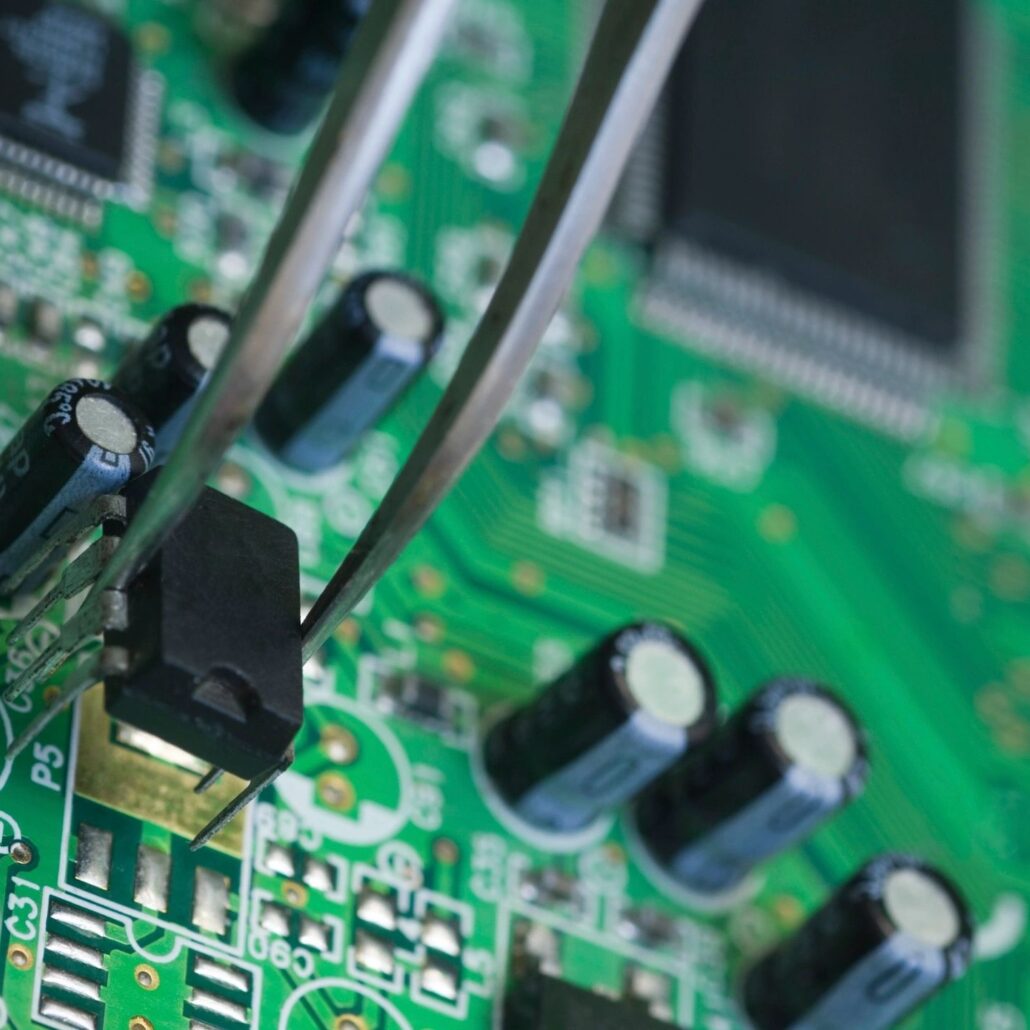

Norway Labs offers reverse engineering services for both populated and depopulated printed circuit boards (PCBs). The process starts with one of our technicians carefully documenting the board, including taking detailed pictures of the board and its components. Once the board is documented, our technicians carefully remove the components and measure them, noting the reference designator for each component. If a part is obsolete, we work to find you an appropriate substitute part that will match the specifications of the original component. After the board has been depopulated, it is scanned into our Gerber generation system. Each layer is then sanded, cleaned, and scanned. These files are then compiled into the final Gerber for the board, which can be sent to a manufacturer to be printed. If you are looking for file types other than Gerber, please contact us for more details.

BOM Creation

Norway Labs is proud to offer Bill of Materials (BOM) creation. We utilize state-of-the-art equipment, such as our LCR meter and Air-Vac system, remove components from PCBs and measure them. Our experience in electronics allows us to correctly identify the components needed or identify a good replacement component if the original is no longer produced, including programmed IC’s, custom, or obsolete parts. Just ask us about our redesign service.

Gerber Generation

Our technicians utilize a calibrated scanner to accurately capture each layer of the PCB. This is a destructive process where each layer of the board is systematically sanded down to reveal the next layer. These layers are then analyzed in the computer and Gerber is created that maps the traces, pads, and via’s of the board.

Component Inspection

With the current shortage of many electronic components and semiconductors, counterfeit parts have become a growing problem. At Norway Labs, we are able to use our state-of-the-art equipment to analyze a part for common counterfeiting techniques. Our Nordson Dage X-Ray machine is able to see inside parts and our technicians are able to analyze components to see if they match the required specifications.

Frequently Asked Questions

Below are some frequently asked questions about the reverse engineering process. If these do not answer your question, please feel free to contact us by clicking the contact button at the bottom of this page or giving us a call at (503) 924-5846.

Do I get my board back at the end of the Gerber process?

No. If you are having Gerber of your PCB generated, the entire board must be sanded down and destroyed in order for us to capture the interior layers and traces.

What happens when a part on my board is no longer produced?

If you have obsolete parts on your board, we will work to analyze the part and find the best replacement part that is currently in production.

Do I get a prototype board at the end of this process?

We specialize in BOM creation and Gerber generation of boards, not manufacturing. However, we have worked with manufacturers to produce projects in the past and if you want help coordinating your prototype creation, please ask in your initial request for a quote.

Can I get schematics for my board?

Our base gerber generation does not come with schematics, just the gerber files needed for manufacturing. If you are also looking for schematics, please let our customer service rep know when you reach out.

What does component inspection entail?

Component inspection involves us comparing the specifications of the orginal part to the part you provide us. This can include checking to ensure that there is dye in the part or checking to ensure the part is measuring at the correct levels. To find out more, please reach out to one of our representatives.